Turbopump Development Project

Project Manager: Prof. Dr. Erkan Ayder

Organization Supporting the Project: Roketsan A.Ş. - ITUNOVA

Abstract: The liquid fueled turbopump development project is coming to an end with a team of 15 people consisting of faculty members, research assistants and graduate students of ITU Faculty of Mechanical Engineering.

Within the scope of the project, the design of turbopumps with 25 kN, 100 kN and 200 kN thrusts, which will be used for propulsion of the last modules of rockets that will be used for placing satellites in the low earth orbit, is being carried out.

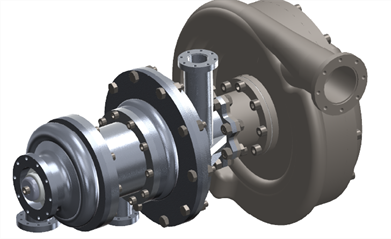

The scope of the design includes the fuel pump, the oxidizer pump, the turbine, the sealing elements, the balancing elements, etc. The design is interdisciplinary and is carried out in collaboration with the mechanical design, hydromechanics, rotor dynamics, structural analysis, materials and project management teams. The project, which started three years ago, is coming to an end. An assembly of the turbopump is given below.

The project is carried out jointly with ROKETSAN A.Ş. through İTÜNOVA Technology Transfer Office.

Lightening and Improving Acoustic Properties of Polyester Matrix Glass Fiber Reinforced Composites for the Automotive Industry with Carbon Nanotube and/or Graphene Additives

Project Manager: Prof. Dr. Levent Trabzon

Organization Supporting the Project: TEYDEP 1505 University-Industry Cooperation Support Program

Vibroacoustically Improved Compressor Design

Project Manager: Assoc. Prof. Dr. Osman Taha SEN

Organization Supporting the Project: Dalgakıran Mak. San. ve Tic. A.Ş. (İTUNOVA)

Abstract: Within the scope of the project, studies were carried out to improve the acoustic performance of the existing two-stage screw compressor. In this context, sound pressure and pneumatic line pressures were measured under different operating conditions . The source of the resulting sound has been determined and appropriate solution suggestions have been developed.

Improving the Acoustic and Vibration Performance of Diesel Generators with Passive Control Approaches

Project Manager: Assoc. Prof. Dr. Osman Taha SEN

Organization Supporting the Project: AKSA Jeneratör San. A.Ş. (ITUNOVA)

Summary: Within the scope of the project, vibration and noise performance analysis of an existing diesel generator is carried out. In this context, acceleration measurements were made from different regions while the generator was operating under certain load and speed conditions. In addition, permeability measurements were made on the wedges connecting the internal combustion engine and electrical motor to the body. Vibration permeability analyzes of the currently used wedges were made. In addition, critical frequency values were obtained by modal tests carried out on the machine assembly. In the later stages of the project , the acoustic problems on the system will be focused on.

Development of action fans used in air conditioning systems

Project Manager: Prof. Dr. Tahsin ENGIN

Organization Supporting the Project: TEYDEP-1505 (BVN Havalandırma Sistemleri A.Ş.)

Abstract: The action fans, which are the subject of the project, include ventilation, drying, heating, cooling, etc. used for purposes and needed wherever there is a need for forced air; It is indispensable equipment of human life and industry. Electricity consumption of fans has a share of 16% in total electricity consumption. Even small improvements in equipment with such a large consumption share will significantly reduce the total electricity consumption.

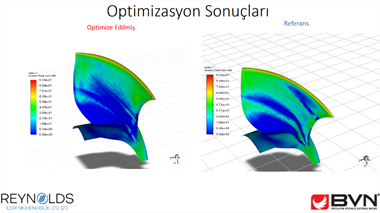

Within the scope of this project, a CFD-based performance analysis will be carried out with the design set to be created by parametricizing all geometric parameters representing the action fan, and an axial fan design methodology can be created for the determined diameter.

Prof. Dr. Tahsin ENGIN

Cooling towers using unique fans to be developed within the scope of this study are structures designed to provide cooling water to industrial facilities for different purposes. Dimensions are determined according to the cooling load and physical limitations. Industrial cooling towers are used in natural gas processing plants, petrochemical plants, oil refineries and power plants.

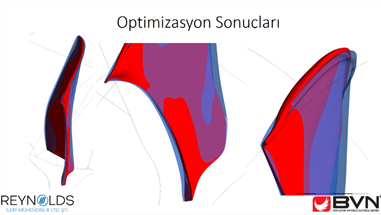

Within the scope of this study, the original biplane product family will be created by optimizing with ANSYS RSO and Adjoint solver optimization tool for every 2 feet between 14 feet and 34 feet. For the CFD-based design methodology to be developed for this product family to be created, it is expected to determine the blade angle of a fan that can provide the specified flow and pressure at the specified diameter.

<grammarly-desktop-integration data-grammarly-shadow-root="true"></grammarly-desktop-integration>